Successfully carrying out planned repairs of galvanized and colored lines of Mobarake Steel Company

The manager of coated and final cold rolled products of Mubarakeh Steel announced the successful completion of planned repairs (shotdown) of the first six months of galvanized and colored lines in June 1402.

Mohsen Zare said in this regard: With the efforts of Mobarakeh Steel employees and contractors and business partners of this company, the planned seven-day repairs of the galvanizing unit with the performance of about 8206 man-hours and the seven-day planned repairs of the color sheet line with the performance of 5060 man-hours were successfully and with acceptable quality. It was done in a completely safe environment.

In the same context, Alireza Gandamkar, the head of Mubarake steel galvanizing unit, also said: the huge volume of activities and the limited time for carrying out the activities required detailed planning and holding numerous meetings before and during the shot down. Colleagues in the galvanizing unit with the participation of the repair technical office were able to successfully achieve all the goals of Shotdown by relying on their knowledge and experience and the ability and expertise of employees and contractors.

Yadullah Kohi, the head of Mobarakeh Steel color unit, while expressing his satisfaction with the quality of the performance of employees and contractors in the color line shot-down, said: removing the interference of work activities in the shot-down and carrying out activities safely in this shot-down is due to the strict control of the maintenance plans and the monitoring of the project control plan in It was during the shotdown that the colleagues in the color sheet unit were able to do it well.

He listed the most important maintenance activities in the color sheet unit as follows: replacement of 8 bridle rollers, 16 rollers and brushes in the washing part, and 10 water quench rollers, installation and operation of the L.E.L. alarm system, complete mechanical service of 18 fans, service of 32 Engine number and disassembly and calibration of 21 sensors of precise instruments, installation of the power center panel of the new reeling line, disassembly and assembly and shot blasting of the output segment, replacement and repair of line waste incinerators, crack test of 36 rollers of line accumulators, complete disassembly of the steam path of galvanized and sheet lines Color and modify and install their extensions.In conclusion, Afshin Naderi Mehr thanks the support of the management of the cold rolling area and the efforts of the employees of the galvanized and colored units, as well as the cooperation of the units of the Technical Office of Repairs, Central Repairs, Technical Inspection, Central Repair Station, Refractory Repairs of the Districts and other colleagues and contractors who played a role in the realization of this task. did, thanked and appreciated.

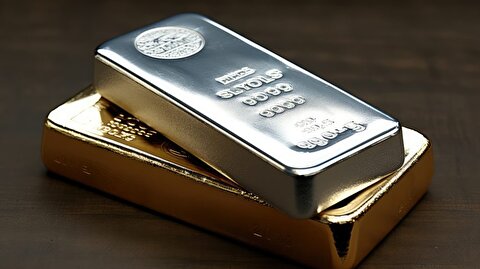

Zimbabwe labs overwhelmed as gold rally spurs exploration, miner says

Cochilco maintains copper price forecast for 2025 and 2026

Samarco gets court approval to exit bankruptcy proceedings

Gold price stays flat following July inflation data

Mosaic to sell Brazil potash mine in $27M deal amid tariff and demand pressures

HSBC sees silver benefiting from gold strength, lifts forecast

Hindustan Zinc to invest $438 million to build reprocessing plant

Glencore seeks $13 billion in incentives for Argentina copper projects

Samarco gets court approval to exit bankruptcy proceedings

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

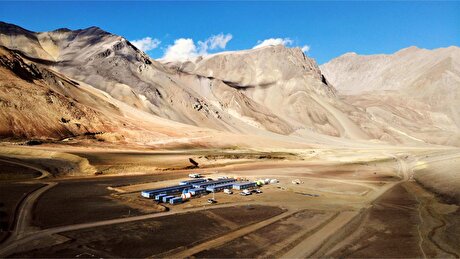

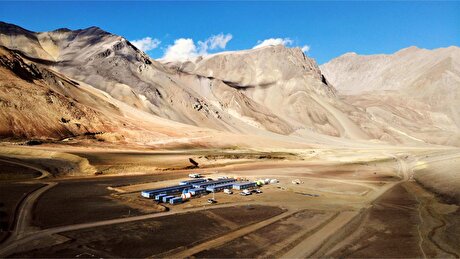

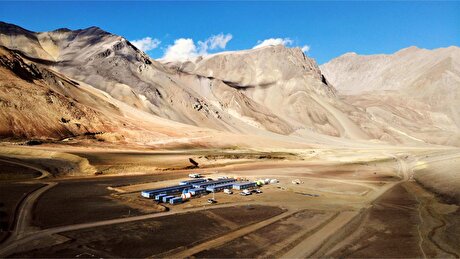

Afghanistan says China seeks its participation in Belt and Road Initiative

Gold price edges up as market awaits Fed minutes, Powell speech

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper

Glencore seeks $13 billion in incentives for Argentina copper projects

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

Afghanistan says China seeks its participation in Belt and Road Initiative

Gold price edges up as market awaits Fed minutes, Powell speech

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper

Glencore seeks $13 billion in incentives for Argentina copper projects