CEO of Arfa Steel Co.: Use of technology is not luxury but a compulsory

Having the experience of managing leading companies such as Khouzestan Steel Co. and Hormozgan Steel Co. in the past decades, he underlines that considering the challenges facing Iran in reducing energy and raw materials, the country has to take a step to do something.

According to him, using technology is not a luxury approach but a necessity, and it has to be compulsory to cut the costs.

"Arfa Steel Co. is in the Center of Iran and, for the time being, our market is considered domestic. If someday the roller manufacturers decide not to buy our ingots and start importing the product, we will defiantly be confronted by a serious problem. This happened in 2015 when

the cost of per kilo production of the ingot was 35 cents, and we had no choice but selling the product at the lower price of 25 cents," he clarified.

Referring to the impact of global prices on the raw materials of steel production, he noted, "The products such as graphite electrode, refractories, and ferroalloys are all offered at world prices.

Global turbulence has led to an increase in the price of the graphite electrode. Previously, the cost of purchasing per tonne electrode from German was €2500, but recently Khouzestan Steel Co. has bought the product at the price of €48,000. Unfortunately, it is not the end of the story, and the new price has reached $8,000."

Khayat admits that the global requirements will lead to an increase in the energy prices in Iran, as well.

Since the Government of Mahmoud Ahmadinejad (2005–13), there was a decline in the allocation of the subsidiary to energy which resulted in higher production costs. The salary is another issue to be considered because, in Iran,an expert with about 2-3 years of experience is entitled to minimum payment of $1,000.

CEO of Arfa Steel Co. stated that there was a time when the low-wage workforce was considered as an advantage for the companies but nowadays it is not so.Even now, the payment in Iran is lower than that in some other countries.

"It is an undeniable fact that in Iran the productivity of workforce in steel production or even in other industries is low. The use of new technologies is less labor-intensive and will also increase the productivity of workforce due to employing qualified and educated people. Under such condition, there will be a boost in the corporate culture as well," he pointed out.

On the problem of inadequate water supply,the official said, "Companies such as Gol-e-Gohar Iron Ore Co. and Chadormalu Mining & Industrial Co. are facing the problem of water shortage because the steel plants are set up in the desert.However, there are companies

all over the world that have succeeded in reducing water consumption up to 50%. For example, in some plants, the cooling tower system is turned into a closed system to prevent water evaporation."

Khayat underlined that currently, the cooling tower system is open in Iran. So the water fetched from the well will be evaporated at the top of the cooling tower. Not only the water consumption will be increased, but also it is harmful to the environment."

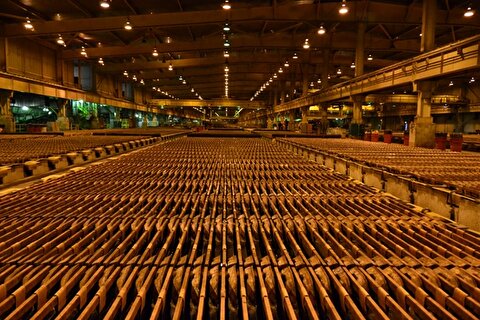

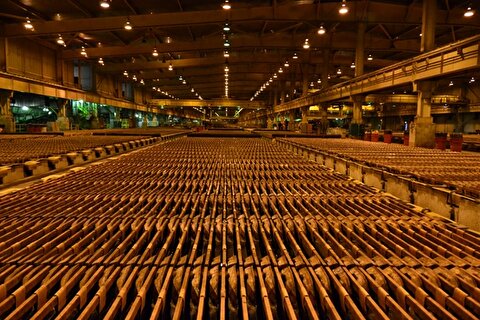

Signaling a new method developed in Direct Reduction, he said," In the Direct Reduction System, for the production of sponge iron, the electric arc furnace is heated up to 850 0°C. Based on the old method, the produced sponge iron was first cooled and then re-entered into the electric arc furnace.There it reached 1600°C temperature.

If the same product enters the electric arc furnace, with a temperature of about 800°C degrees, there will be a significant reduction in energy consumption."

Hot Charging Technology

CEO of Arfa Steel Co. announced that the first steel plant applying Hot Charging Technology will be launched by Chadormalu Mining & Industrial Co. in Iran.Besides, the company's Mega Module Direct Reduction will be inaugurated in the coming year.

The hot sponge iron of this MIDREX mega-module enters the electric arc furnace. In this process, the drop in temperature is slight.The entire cost of energy, refractories, and electrodes will be reduced by applying this method. Put it in other words; it is the cost price that is brought down.The consumption of other additives will indirectly be reduced,as well.The Hot Charging Technology has not been applied in Iran yet, and according to Khayat, Chadormalu Mining & Industrial Co.is determinedly pursuing the method.

He clarified that using these methods does not mean to apply a luxury approach as it will lead to a decrease in the consumption of energy,and as a result a reduction in cost.

"We are left with no alternative but to use new methods against the rise of raw material prices.Last year, Arfa Steel Company faced 15% increase in workforce payment, 15 %-20% rise in shipping costs, and four times increase in the price of graphite electrode, while the marginal profit of the company was merely 15%. Meanwhile, there was no increase in the price of steel ingots due to the national recession," he stated.

Khayat holds that the companies were previously state-owned, and the drop did not bring about dramatic effects on their function, but now private companies are not able to survive as the prices are rising continuously.

"The owner of the plant may decide to undertake different approach. For example,to halt the production of the electric arc furnace and to focus solely on output and sale of concentrates and iron ore pellets," he explained.

Remarking upon the Arfa Steel Company's stand on using the new technology of sponge iron production, he said, "Our situation is slightly different. The Direct Reduction Section should be located above the steel making so that the sponge iron will flow smoothly into the electric arc furnace. In our company, sponge iron plant is located lower because such a pattern was not predicted in the process of designing. Besides, Direct Reduction and electric arc furnace are not close together," he said.

He unveiled that the cost and benefits of the Hot Charging Method are under study to see whether it is applicable or not. However, the new plants will incorporate some novel design features to apply new approaches.

JCPOA impact

Iran has a history of cooperation with European and Western companies in the technology sector, but due to the sanctions imposed against the country, China and Eastern countries were replaced.

CEO of Arfa Steel Company highlights that China has no innovative technology to share as it tends to replicate other countries.

"JCPOA was a determining factor in removing the barriers against technology transfer. We have also imported the new Hot Charge

Technology from an advanced country.The prospect of relationships is promising.European and Western nations would also like

to develop relations with Iran," he noted.

Khayat pointed out that Iran's progress in the Middle East has been continuous and the country's growth has been sustained.

"The country's condition is very favorable in the MENA region and Iran and its foreign partners, especially the Europeans, can realize

significant profits," he said in conclusion.

NexMetals receives EXIM letter for potential $150M loan

Lifezone Metals buys BHP’s stake in Kabanga, estimates $1.6B project value

China quietly issues 2025 rare earth quotas

Gold price eases after Trump downplays clash with Fed chair Powell

BHP, Lundin JV extends useful life of Argentina copper mine

BHP delays Jansen potash mine, blows budget by 30%

Teck approves $2.4B expansion of Highland Valley Copper

KoBold signs Congo deal to boost US mineral supply

Northern Dynasty extends losses as it seeks court resolution on Pebble project veto

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Finland reclaims mining crown as Canada loses ground

Gold price down 1% on strong US economic data

Trump’s deep-sea mining push defies treaties, stirs alarm

Chile’s 2025 vote puts mining sector’s future on the line

Gold price retreats to near 3-week low on US-EU trade deal

China’s lithium markets gripped by possible supply disruptions

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Gold price down 1% on strong US economic data

Trump’s deep-sea mining push defies treaties, stirs alarm

Chile’s 2025 vote puts mining sector’s future on the line

Gold price retreats to near 3-week low on US-EU trade deal

China’s lithium markets gripped by possible supply disruptions