MSC’s energy consumption is lower than global average

Javad Nili made the comment in an interview with Steel Newsletter and said the company’s Pelletizing Unit has set an example for global firms when it comes to energy consumption.

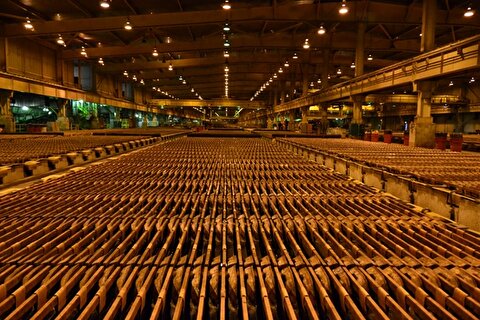

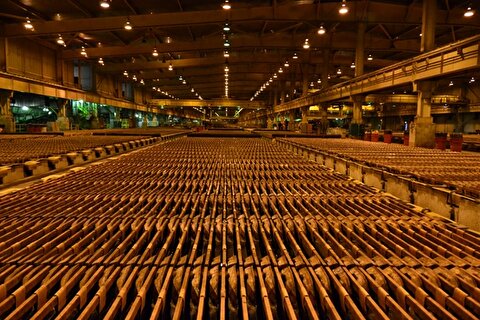

He referred to the company’s measures involving optimal use of energy in the production process and application of energy optimization to production of data-x-items with higher added value. “The Iron-Making Unit uses gas to produce sponge iron. In fact, the process to turn pellets into sponge iron accounts for more than 65 percent of the gas that comes into the company. Less than 20 percent of the incoming gas is used by the MSC Power Plant to generate electricity for internal use.”

Nili further said the electricity generated by MSC Power Plant accounts for over 25 percent of the electricity Mobarakeh Steel Company uses in the production process. “The remainder is provided by the national grid. According to the electricity consumption diagrams, the Steelmaking Unit and the electric arc furnaces use the lion’s share of the company’s electricity.”

A comparison of energy consumption at different units and plants at MSC with other steelmakers whose performance is between 50 and 70percent of the world’s top steelmakers shows that MSC’s energy consumption is ideal both nationally and internationally, he said. “In pelletizing, the national standard for energy consumption is 47.1 gigajoules per ton, while the global average is 7.1 gigajoules per ton. But in Mobarakeh Steel Company the average stands at 92.0 gigajoules per ton. This shows that MSC’s Pelletizing Unit has set an energy consumption example for others to follow.”

Nili then touched upon the company’s environmental achievements and said implementation in the power plant of a project on the heat recovery steam generator (HRSG) has resulted in the registration of the project as a Clean Development Mechanism (CDM) at the United Nations Framework Convention on Climate Change on June 21, 2012.

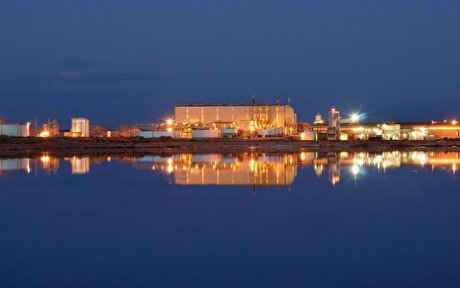

Mobarakeh Steel Company has taken valuable steps toward maximal reduction of water consumption and protection of the environment by investing in a project designed to develop a network of collecting, treating and recycling wastewater of nine towns in Mobarakeh and Lenjan districts in Isfahan Province, he added.

He went on to say, “MSC’s special use of industrial water stood at 3.36 cubic meters per ton of crude steel production between March 21and July 22, 2018. Reuse of the water coming out of the wastewater treatment facility helped MSC produce 5.423 million tons of crude steel by January 20, 2019 and consume 2.75 cubic meters of [industrial] water per ton of slabs produced. The company’s breakthrough is now a role model in the world.”

Gold price eases after Trump downplays clash with Fed chair Powell

Copper price hits new record as tariff deadline looms

Brazil producers look to halt pig iron output as US tariff threat crimps demand

Three workers rescued after 60 hours trapped in Canada mine

US targets mine waste to boost local critical minerals supply

Titan Mining targets Q4 2025 to become only integrated US graphite producer

Energy Fuels surges to 3-year high as it begins heavy rare earth production

Glencore workers brace for layoffs on looming Mount Isa shutdown

Resolute publishes initial resource for satellite deposit near Senegal mine

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Finland reclaims mining crown as Canada loses ground

Gold price down 1% on strong US economic data

Trump’s deep-sea mining push defies treaties, stirs alarm

Chile’s 2025 vote puts mining sector’s future on the line

Gold price retreats to near 3-week low on US-EU trade deal

China’s lithium markets gripped by possible supply disruptions

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Gold price down 1% on strong US economic data

Trump’s deep-sea mining push defies treaties, stirs alarm

Chile’s 2025 vote puts mining sector’s future on the line

Gold price retreats to near 3-week low on US-EU trade deal

China’s lithium markets gripped by possible supply disruptions