ECIC 2016 (7th European Coke and Ironmaking Congress)

SCOPE and TOPICS:

The Congress will bring together a wide range of experts, coming from plant operation, plant suppliers and research institutes, who share expertise in:

- Coke making

- Iron ore production and handling

- Sintering

- Pelletising

- Blast furnace iron making

- Direct reduction

- Smelting reduction

- Environmental control in iron making

- CO2 reduction and energy saving

- Recycling of in-plant residues

Important Dates:

Abstract submission: 01 November 2015

Notification of Acceptance: 15 January 2016

Full Paper Submission: 31 May 2016

Registration Deadline: 31 August 2016

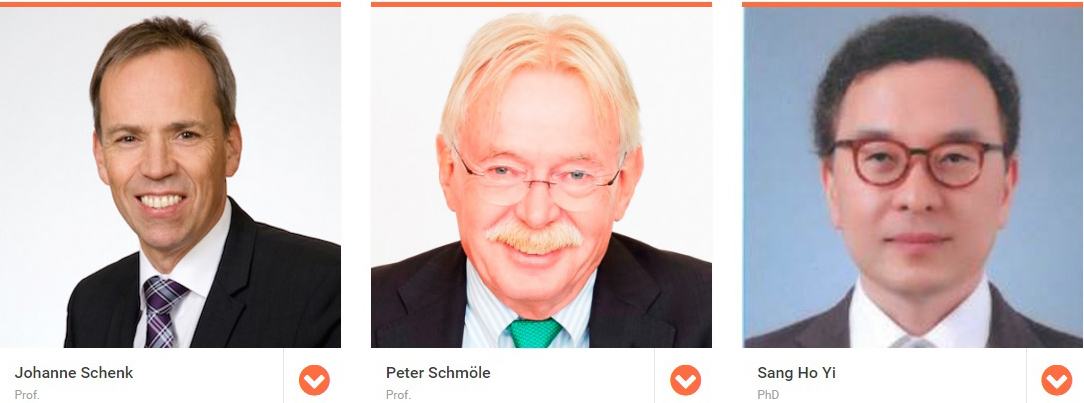

Conference Chairman:

Johannes Schenk

Montanuniversität Leoben, Austria

Organizing Committee:

Bruno Hribernik, ASMET

Melanie Baumgartner, ASMET

Scientific Committee:

| Böhm | Christian | Primetals Technologies GmbH | Austria |

| Bol | Luc | Tata Steel IJmuiden B.V. | Netherlands |

| Buergler | Thomas | voestalpine Stahl GmbH and K1-MET GmbH | Austria |

| Dimastromatteo | Vincenzo | Arvedi Steel Technology | Italy |

| Luengen | Hans Bodo | Steel Institute VDEh | Germany |

| Masuth | Markus | ArcelorMittal Bottrop GmbH | Germany |

| Noldin | Jose Henrique | LHOIST S.A. | Belgium |

| Ofner | Hanspeter | Primetals Technologies GmbH | Austria |

| Peters | Michael | ThyssenKrupp Steel Europe AG | Germany |

| Schmöle | Peter | ThyssenKrupp Steel Europe AG | Germany |

| Schuster | Elmar | voestalpine Stahl Donawitz GmbH | Austria |

| Siuka | Dieter | Primetals Technologies GmbH | Austria |

| Vetoniemi | Markku | SSAB Europe Oy | Finland |

Keynote Speaker:

Plant Visits

Tour 1 (Coke oven plant): Five batteries with total 200 ovens and a chamber volume of 21,5 m3 are in operation. This only one coke oven plant in Austria generates approx. 1,3 million metric tons of blast furnace coke from 1,8 million metric tons of coking coal each year. All batteries have been modernized and equipped with systems for a high level of environmental protection and automatization as well as state-of-the art coal unloading and preparation equipment.

Tour 2 (Sinter plant): One sinter strand with a suction area of 222 m2 and layer hight of 700 mm produces approx. 2,8 million metric tons of sinter per year. The plant is equipped with selective partial offgas recirculation system, a dry offgas cleaning system (MEROS) and a selective catalytic reduction (SCR) DeNOx system and is the benchmark for high productivity sintering operation with maximum emission reduction.

Tour 3 (Blast furnace plant): Ironmaking in Linz is performed with 3 blast furnaces, each equipped with PCI and injection equipment for several other alternative reducing agents like plastics, oil, crude tar, NF and COG. Approx. 4,8 million metric tons of hot metal per year are produced with BF A (hearth diameter 12,0 m) and BF 5/6 (hearth diameter 8,0 m). The latest developments in charging technology, process automatization and measuring techniques lead to an outstanding blast furnace performance.

Zimbabwe labs overwhelmed as gold rally spurs exploration, miner says

Cochilco maintains copper price forecast for 2025 and 2026

Samarco gets court approval to exit bankruptcy proceedings

Gold price stays flat following July inflation data

Mosaic to sell Brazil potash mine in $27M deal amid tariff and demand pressures

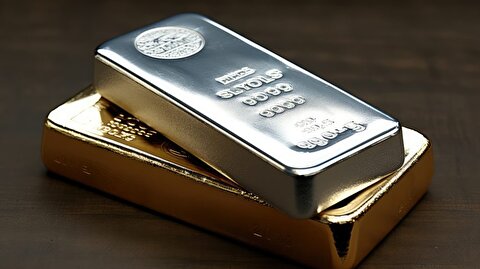

HSBC sees silver benefiting from gold strength, lifts forecast

Hindustan Zinc to invest $438 million to build reprocessing plant

Glencore seeks $13 billion in incentives for Argentina copper projects

Samarco gets court approval to exit bankruptcy proceedings

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

Afghanistan says China seeks its participation in Belt and Road Initiative

Gold price edges up as market awaits Fed minutes, Powell speech

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper

Glencore seeks $13 billion in incentives for Argentina copper projects

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

Afghanistan says China seeks its participation in Belt and Road Initiative

Gold price edges up as market awaits Fed minutes, Powell speech

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper

Glencore seeks $13 billion in incentives for Argentina copper projects