Hormozgan Steel Company (HOSCO) a leading manufacturer of advanced steels

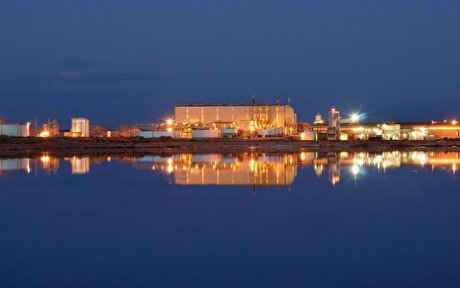

HOSCO has got a suitably strategic location including four kilometers distance and adjacent to the blue waters of the Persian Gulf in order to supply constant water and export, close to the gigantic gas fields, in close proximity to huge reservoirs of iron ore mines and Shahid Rajaei Port Complex. Also, it has an important infrastructures such as road, maritime, rail and airport transportation.

Hormozgan Steel Company (HOSCO) is an important plant in Iran because it is the most advanced steel mill and the fourth largest in terms of volume of production. Especially due to the proximity of the Persian Gulf , HOSCO has got a valuable opportunity and great location for export. The following interview was conducted with Amir Masoud Haratian – CEO of Hormozgan Steel Company (HOSCO):

CEO of HOSCO – Amir Masoud Haratian – at first said about the history of HOSCO and continued after an international tender and the formation of an international consortium on June 2006, the construction of the plant began. The first unit i.e. the Direct Reduction Plant (Iron-making Plant) with an annual capacity of 1,650,000 tons per annum of sponge iron was finally completed in just 32 months, an unprecedented record for the construction of such plants in the country and was launched in March 2009. Then on 1 January 2012 with the completion of steel-making unit and slab production , HOSCO was officially commissioned.

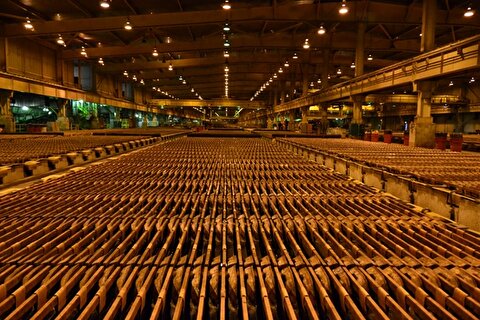

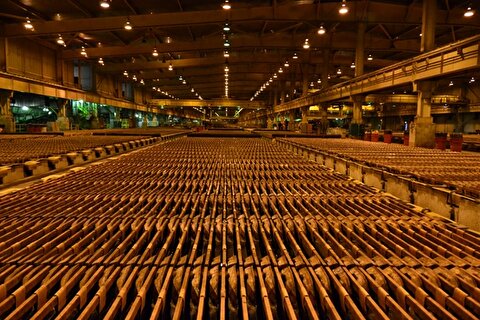

By referring to the products of this very plant he added , the complex has a nominal slab output capacity of 1.5 million tons per year with the thickness of 200 and 250 mm., width 900 to 2000 mm. and length of 6000 to 12000 mm. The company is capable of producing intermediate products such as 1,650,000 tons of sponge iron per year , 90,000 tons of lime per year, 7500 normal cubic meters of oxygen per hour, 18,000 normal cubic meters of nitrogen per hour, and 120 normal cubic meters of argon per hour. The slabs produced at HOSCO are mainly carbon steel grades and used for down-stream roll and sheet in shape of hot strip, cold rolling as well as wide plate mills. HOSCO slabs in hot rolling line are mostly used for profile making, oil and water pipes, heavy steel structures and pressurized vessels. The hot coils rolled to cold products will be used for car body sheets, home appliances sheets including refrigerator , heater as well as special applications for coating lines such as tinplated and galvanized sheets.

“One of the plans of HOSCO is the development of slab production from current 1.5 million tons to 3 million tons per year”, he announced and continued according to the trip made by the President of I.R. IRAN to Italy the contract in question was signed with one of the European companies and study sessions and expert discussions for the development of the plan are being held by the related working group.

Haratian declared , HOSCO products conform to the recent universal standards such as ISIRI (Islamic Republic of Iran Standard Institute), API , AISI / SAE, ASTM (USA), BS (UK), DIN (Germany), EN (European Union), JIS (Japan), ISG (domestic standard by HOSCO).

CEO of HOSCO outlined some features of HOSCO production lines such as applying of pollution control system “Dog HOUSE” for controlling and reducing of pollution, producing of the widest slab in Iran with the width of 2000 mm. for production of oil and gas tubes (pipeline applications), the highest slab casting speed by maximum speed of 1.6 meters per minute in the country in order to increase production efficiency , using 95% sponge iron as EAF metallic charge (possibility of storing 60 tons hot molten steel in EAF) reducing the dependency of HOSCO on scrap market and its ever fluctuating prices, existence of Vertical Bending CCM line for the production of high quality melting steels, increasing the production of high quality melting and reducing the impurities , and the possibility to change the slab width during the casting in order to reduce the preparation time.

He expressed the other characteristic of HOSCO such as having one of the most advanced water desalination in south of Iran in order to use sea water for required processes of the plant, producing of high carbon steels for production of HSLA (High Strength Low Alloys) grades, producing of 46 ton slabs – the heaviest in the country , producing of lime in a modern concept twin vertical furnace, the EAF slag is discharged onto the ground (clean slag pit concept) eliminating the need for slag pot and its time consuming handling and the tap-to-tap time is shortened and increasing the production efficiency.

Haratian stated HOSCO’s production grades are as follow : Gr.A, API X42, A537, A516T, A537, CK45, P460, 34CrMo4, and also API X60, ST52, ST44, ST37, ST22.

By referring to the place and importance of customers in HOSCO and about the plans for communicating with customers some issues have been considered and mentioned them such as establishing of optimal communications with customers and also providing services according to international standards in the shortest time, improving the level of the quality of products, executing of the quality improvement projects in partnership with customers, expanding the variety of new products to meet the needs and expectations of customers along with understanding of present and future needs in order to gain the trust and loyalty and customer satisfaction, the implementation of Customer Relationship Management System (CRM) in order to facilitate sales services to customers.

By pointing out to the importance of management system and excellence for HOSCO he added, organizational neatness systems (5S Concept), suggestion system, energy management system based on ISO50001 : 2011 standard, laboratory quality management system and receiving the international certification of ISO17025 : 2015 is now running, and the management systems which are being established are quality management system ISO9001 : 2015, strategic management system and Total Quality Management (TQ) . Also HOSCO nominated for international knowledge management award (MAKE) in intellectual capital and training effectiveness sectors.

Gold price eases after Trump downplays clash with Fed chair Powell

Copper price hits new record as tariff deadline looms

Brazil producers look to halt pig iron output as US tariff threat crimps demand

Three workers rescued after 60 hours trapped in Canada mine

Gold price could hit $4,000 by year-end, says Fidelity

US targets mine waste to boost local critical minerals supply

Energy Fuels surges to 3-year high as it begins heavy rare earth production

Glencore workers brace for layoffs on looming Mount Isa shutdown

Chile’s 2025 vote puts mining sector’s future on the line

Kinross divests entire 12% stake in Yukon-focused White Gold

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Finland reclaims mining crown as Canada loses ground

Gold price down 1% on strong US economic data

Trump’s deep-sea mining push defies treaties, stirs alarm

Chile’s 2025 vote puts mining sector’s future on the line

Gold price retreats to near 3-week low on US-EU trade deal

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Gold price down 1% on strong US economic data

Trump’s deep-sea mining push defies treaties, stirs alarm

Chile’s 2025 vote puts mining sector’s future on the line

Gold price retreats to near 3-week low on US-EU trade deal

China’s lithium markets gripped by possible supply disruptions