China to reclassify high-purity scrap metal

Under an unpublished proposal seen by Argus, the required copper and aluminium content in Chinese scrap imports will be raised and impurities minimised. The proposal listed mandatory detailed, complicated testing procedures for metal content, impurity and sizes of scrap metal.

The list of requirements and processes are stringent, which is expected to increase the cost of exporting scrap to China. But scrap metal that meets the newly proposed criteria will be reclassified as raw material and consequently be subject to fewer import restrictions.

China had already implemented scrap import restrictions earlier in the summer, which required all scrap metal importers in China to obtain import licences issued under approved quarterly quotas from 1 July before they can receive any material.

The total of all copper scrap import quotas approved to date is 484,217t, with aluminium at 405,416t and ferrous at 22,688t.

The Chinese national non-ferrous metals standardisation technical committee, with the assistance of downstream manufacturers, processors and producers, has proposed new standards for copper, brass and aluminium alloy casting scrap imports into China. The committee sent the proposed scrap standards to 35 selected firms and trade associations in September and the consultation period ended by the end of the month.

The committee gathered in Beijing on 10 October for an internal conference to discuss the reform and develop a final version of the unpublished proposal. The final version of the policy is expected to be formally announced at the end of this year.

The details outlined below pertain to the unpublished proposal and could be subject to change following the implementation of the final policy.

Aluminium alloy scrap

The committee plans to implement a long-term plan for a recycling policy similar to the Home Recycling Law in Japan, which requires a minimum recovery rate of aluminium at 95pc in household appliances.

"In order to avoid the environmental pollution caused by producing primary aluminium from bauxite and the huge energy waste, the developed countries have developed related product recycling laws, which require aluminium products manufacturers to undertake the resource and environmental responsibility in their supply chain," the committee said.

Aluminium alloy scrap that meets the set standards of the new policy will not be classified as "solid waste" and can be imported freely as raw material.

Under the new rules, aluminium alloy casting scrap must not contain lead, tin, antimony and bismuth.

Cast scrap must be at least 98pc pure, with just a 0.7pc allowance for metallic impurity.

Zorba (shredded aluminium scrap) must be at least 91pc pure, with a 0.9pc allowance for metallic impurity.

The committee also proposed that the recovery rate of aluminium casts must be at least 95pc, with zorba at 92pc. This will be tested in every sampled batch.

The material must not contain visible dust, grease, mud, paint, ink, corrosive material, adhesive tapes and boards, plastic, felt, paper, glass fibre, and non-metallic material.

Aluminium piston, automotive and aviation casts should not be mixed with busheling. Cast wheels should not be copper, zinc plated and mixed with other scrap.

Aluminium scrap should be packaged according to sizes (65mm, 28-65mm, 28mm) and should be visually regular. The packaging should contain a description of the scrap, size, weight, aluminium and alloy content, metal content, recovery rate, packaging type, origin and executive standard.

Different sizes of scrap will be labelled according to colours — green for large, yellow for medium and white for small.

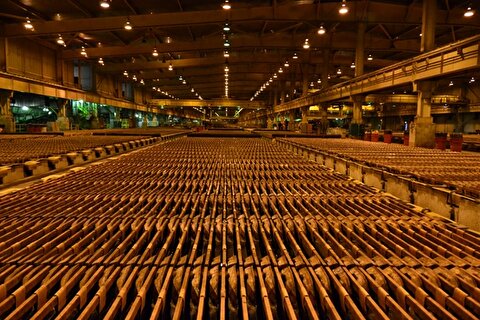

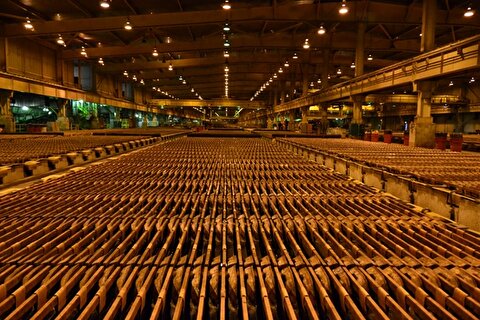

Copper raw material

In the proposal, the committee emphasised the importance of a long-term strategy to reduce China's dependency on copper raw material imports.

"Copper resources' self-sufficiency rate is less than 20pc in China. The domestic copper mine resources are poor, with low and complex ore bodies, resulting in high mining costs. Using recyclable copper as raw material is an important way to alleviate China's current shortage in copper resources," the committee said.

"China's manufacturing industry provides a large number of sufficient and high-quality raw materials to achieve sustainable development of China's manufacturing industry and sustainable supply of non-ferrous metal resources.

"The use of recycled copper raw material will reduce China's long-term dependence on imports, which effectively guarantees the resources demand in China."

Copper scrap imported into China must not contain abandoned bombs, shells and other explosives. Sealed and pressurised containers will be restricted and should not exceed 0.01pc of the total content.

In addition, the raw material imported must not contain cadmium, chromium, lead, arsenic, antimony, selenium, tellurium or cobalt, except in the form of alloys.

The particles of non-metallic contamination in the form of dust, sludge, crystalline salts, metal oxides and fibre should not exceed 2mm in diameter.

Radioactive pollutants will be tested on a batch-by-batch basis. In containers, 5pc of the content will be randomly tested. In bulk shipments, 25t will be tested from every cargo. The weight of every sample will be at least 100kg.

The draft proposal will group recyclable copper into seven categories; RCu-1A, RCu-1B, RCu-2A, RCu-2B, RCU-3A, RCu-3B and RCU-7 (copper wire, products, granules, water-washed copper, turnings, water tanks, plated copper) and 13 sub-categories. The descriptions and requirements are detailed in the relevant accompanying table.

The same restrictions on copper scrap will apply to recyclable brass imports into China, as outlined in the accompanying table.

Gold price eases after Trump downplays clash with Fed chair Powell

Copper price hits new record as tariff deadline looms

Brazil producers look to halt pig iron output as US tariff threat crimps demand

Three workers rescued after 60 hours trapped in Canada mine

Gold price could hit $4,000 by year-end, says Fidelity

US targets mine waste to boost local critical minerals supply

Energy Fuels surges to 3-year high as it begins heavy rare earth production

Glencore workers brace for layoffs on looming Mount Isa shutdown

Chile’s 2025 vote puts mining sector’s future on the line

Kinross divests entire 12% stake in Yukon-focused White Gold

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Finland reclaims mining crown as Canada loses ground

Gold price down 1% on strong US economic data

Trump’s deep-sea mining push defies treaties, stirs alarm

Chile’s 2025 vote puts mining sector’s future on the line

Gold price retreats to near 3-week low on US-EU trade deal

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Gold price down 1% on strong US economic data

Trump’s deep-sea mining push defies treaties, stirs alarm

Chile’s 2025 vote puts mining sector’s future on the line

Gold price retreats to near 3-week low on US-EU trade deal

China’s lithium markets gripped by possible supply disruptions