Q&A: Viswa advises on additional bunkers testing

Should shipowners run additional specification tests to the standard specifications test they already run? If so what are they and how long does it take to get the results? Should shipowners be testing for catfines? If so is this a standard test?

Yes. Since 0.5pc sulphur fuel oils are generally classified as residual fuels under ISO 8217, we recommend that the client carry out stability, gas chromatography mass spectrometry (GCMS) screening to identify contaminants and fourier transform infrared (FTIR) screening to identify fatty acid methyl esters(FAMEs).Catfines will be tested as part of the standard ISO 8217 testing scope.

Some suppliers in the US Gulf coast have talked about selling 0.5pc sulphur vacuum gasoil (VGO) as IMO 2020 complaint fuel. Do you know if 0.5pc sulphur VGO would be compatible with 0.5pc sulphur residual fuel oil?

VGOs are predominantly paraffinic so the possibility of their incompatibility is high when they are mixed with aromatic based fuels. In different studies, it is recommended not to mix aromatic fuel with paraffinic fuel.

For vessels that cannot procure 0.5pc sulphur fuel oil at the port they are bunkering, and they buy marine gasoil (MGO) instead to burn in their main engines, what problems do you foresee? What are the lessons learned from 2015, when the Emission Control Areas (ECAs) switched to 0.1pc sulphur fuel from 1pc sulphur fuel?

The changeover from 1pc to 0.1pc sulphur fuel in 2015 in ECA areas did result in numerous problems including a number of blackouts of the California coast. One important lesson learned was the importance of checking the viscosity and not allowing it to drop below 2 centistokes (cst). Some ships installed coolers or chillers for this purpose. The other important lesson was the importance of lubricity. A number of our clients keep lubricity additives in stock in case the 0.1pc sulphur MGO supplied has borderline or off-specification lubricity properties.

What do you think of the International Organization for Standardization's (ISO) Publicly Available Specification (PAS) published the end of September?

At this time there is no specification for 0.5pc sulphur fuel oil products in ISO 8217. There is such a wide difference between the supplies globally from port to port that it is very difficult to come up with an all-encompassing specification. The 0.5pc sulphur fuels vary from the residual fuel oil type (high density, high viscosity but originating from very-low sulfur crude oil) to light-middle distillate type (density 0.87 kg/l, viscosity of about 6cst at 100°C). The viscosity vary widely even within the same grade. For example, some lower viscosity fuels may have other characteristics such as density, carbon residue and catfines typical of higher viscosity grades.

Already hundreds of 0.5pc sulphur fuel oil samples have been tested and typically viscosity falls in the range of 10-380cst and density from 870-991 kg/m3.

Based on PAS, there are several tests recommended for stability and compatibility. One is ASTM D4740 for compatibility. This method is developed for aromatic fuels containing asphaltenes. If a black ring or spot is formed in the middle of the filter paper, asphaltenes have precipitated and the fuels may be incompatible. While some of the new 2020 fuels may be highly paraffinic/waxy fuels. Very paraffinic fuels and distillate blends may show false results, indicating that fuels are incompatible, when they are actually compatible. The false-negative result is due to pigment separation, light wax, and heavy wax. Care should, therefore, be taken when evaluating the results. The ISO 10307 total sediment potential, (TSP) is a stability test. It can be applied for different fuel types (paraffinic or aromatic fuel) but the test will take 24 hours. The ASTM D7060 (Zematra) test is for stability and the ASTM D7112 (PORLA-P value) and the ASTM D7157 (ROFA-S value) tests are for for stability and compatibility. The last three tests can provide further insight into the stability of the fuel by investigating the asphaltene flocculation point. P-value and S-Value methods can predict the compatibility by calculating the P-value and S-value of the blends but it has been shown that calculating these values is not applicable for all blends.

What stands out about the 0.5pc sulphur bunker fuels specifications you have tested thus far, compared with conventional 3.5pc sulphur 380cst fuel oil bunkers?

Based on our available data set, we find that some of the 0.5pc sulphur fuels have a waxy/paraffinic base which may cause wax deposition when the temperature goes below the wax appearance temperature. Some of these fuels contain slurry components (high density, low viscosity fuels) which may cause incompatibility issues after blending.

Do you foresee problems such as low viscosity causing pump failures and leakages due to low viscosity and low lubricity? There is high probability of paraffinic blends making their way into marine bunker market, which will not only increase the need to address higher pour points but also the general cold flow properties of fuels. What can the shipowners do to protect themselves?

Based on our research and finding of major engine manufacturer, viscosity becomes an issue when it falls below 2cst at 40°C. All the 0.50pc sulphur products in the market so far have had a viscosity of 10cst and above. Lubricity becomes an issue when the Sulfur is below 0.05pc sulphur. This has not been an issue with the 0.50pc sulphur products.

But with 0.1pc sulphur marine gasoil (MGO) forming a large part of the bunker market in 2020, both low viscosity and lubricity need to be closely watched for the MGO supplied in the Emission Control Areas.

We have seen two predominant groups of 0.5pc sulphur oils: aromatic based (with lower pour point) and paraffinic based (with higher pour point). At this time the highest pour point we have seen for 0.5pc sulphur fuel oil in 27°C. While within specification, this would mean that the fuel has to be heated to 10 degrees higher than the pour point to prevent the wax portions solidifying. This becomes a greater challenge in winter. It is important to have sufficient heating capacity on board in order to handle these higher paraffinic fuels.

Should shipowners consider changing their bunkering and fuel testing procedures to better protect themselves from 0.5pc sulphur fuel oil-caused engine problems? If so, what procedures would you advise?

It is very important to have a ship implementation plan for every ship. Shipowners should review their fuel transfer filtration and delivery systems and their bunkering arrangements.

If shipowner is planning to mix 0.5pc sulphur fuel oil from two different suppliers in the vessel's bunker tank, what is the lowest level of fuel compatibility they could tolerate without jeopardizing their vessel? How long does it take to run a compatibility test?

A rule of thumb for compatibility used to be that if the two fuels are similar in density and viscosity values, they are likely to be compatible. But with the numerous new blends, this thumb rule may no longer be practical. Based on past experience with the 0.1pc sulphur fuel oils that came into the market in 2015, it is safe to blend 3.5pc sulphur fuel oil and 0.5pc sulphur fuel oil at no more than 2pc to 98pc ratios without checking their compatibility. The compatibility spot test (ASTM D4740) can be carried out onboard in about 90 minutes but this method does not work with all the 0.5pc sulphur fuels. Most of the other tests mentioned can be carried out in the lab in about two hours.

Do you foresee engine problems when shipowners switch from burning 0.5pc sulphur fuel oil in the open seas to burning 0.1pc sulphur marine gasoil at the ports or in the ECAs?

As long as the viscosity and lubricity values are known and correct changeover policies are followed, we do not see a major difference in going from 0.5pc to 0.1pc sulphur. It should be similar to going from 3.5pc to 0.1pc sulphur.

What is the stability test method you would recommend to shipowners bunkering 0.5pc sulphur. How long does it take to run it?

The total sediment potential (TSP) which is assessment and indication of the stability and cleanliness of fuel needs to be tested. This test will take one day and when TSP exceeds 0.1pc, the fuel is considered to be unstable.

Has the bunker contamination problem from the spring/summer of 2018 in the US Gulf, Singapore and Panama changed the way shipowners bunker fuel and test the fuel?

The bunker contamination story in the Houston area, Singapore and Panama was an eye-opener to the shipping industry. Never had there been such huge number of damages over a significant period of time. We saw a lot of our clients request advanced testing such as gas chromatography mass spectrometry (GCMS) for all their bunkers. We also found that a lot of ships waited to get a green flag from the testing lab before using the fuels. On the supplier side there has been an effort to run complete tests on blended fuels, not just for ISO 8217 parameters.

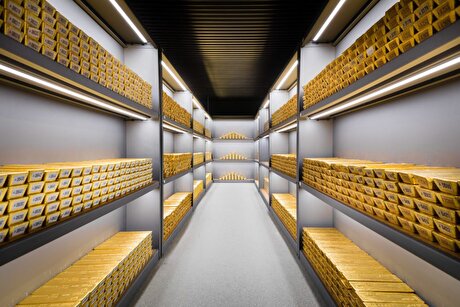

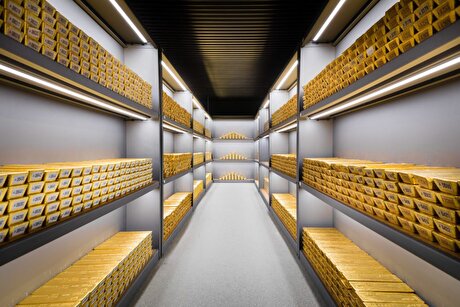

Mali to restart production at Barrick’s Loulo‑Gounkoto gold mine

Copper price surges to highest since March record

Platinum price surges to 11-year high on supply concerns

Energy Fuels’ rare earth JV in Australia receives regulatory OK

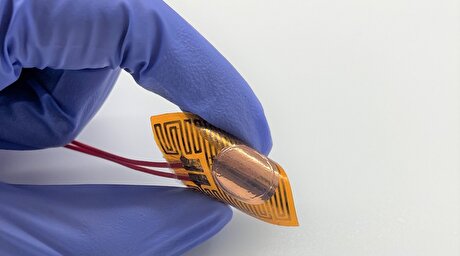

CHART: The brutal economics of EV battery lithium

Cobalt price surges after Congo extends ban

Central Asia Metals ups offer for New World Resources to fend off Kinterra

Gold price falls 2% on US-China trade agreement

Kenorland options three gold projects in Ontario to Centerra

Peru copper transport disrupted as informal miners block roads

Highland Copper gets local support for $50M grant to build Michigan mine

Kinterra takes bidding war for NWR to takeover panel

HSBC ups gold price outlook for 2025 and 2026

Copper price rises to three‑month high amid supply squeeze and trade optimism

Mineral smuggling from Congo to Rwanda at ‘unprecedented levels’, UN says

Chile cuts mining permitting times by up to 70%

B2Gold pours first gold at Nunavut’s Goose mine

Russia base metals sales to China surge, signaling deep reliance

Zambia launches 100MW solar plant supplying First Quantum Minerals

Peru copper transport disrupted as informal miners block roads

Highland Copper gets local support for $50M grant to build Michigan mine

Kinterra takes bidding war for NWR to takeover panel

HSBC ups gold price outlook for 2025 and 2026

Copper price rises to three‑month high amid supply squeeze and trade optimism

Mineral smuggling from Congo to Rwanda at ‘unprecedented levels’, UN says

Chile cuts mining permitting times by up to 70%

B2Gold pours first gold at Nunavut’s Goose mine

Russia base metals sales to China surge, signaling deep reliance