Fresh Impetus to Bauxite Mining Project in Guinea

“The project’s bankable feasibility study carried out by German and British consultants is expected to be concluded by the end of September,” Karbasian said on Monday.

A bankable feasibility study entails the compilation of the results of all other feasibility studies when planning a mining project as well as information on required permits, environmental impact, negotiated contracts and the costs of closing the mine and reclaiming the ground.

According to Karbasian, who is also a deputy minister of industries, mining and trade, two-thirds of the domestic aluminum industry’s demand for raw material are met through imports.

“As we need to have access to dependable resources, cooperation with Guinea can prove instrumental,” he said.

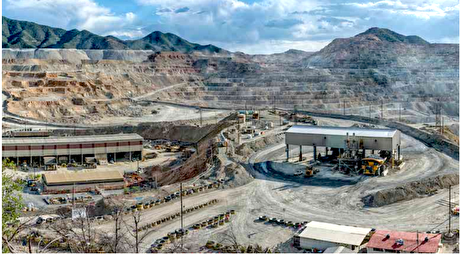

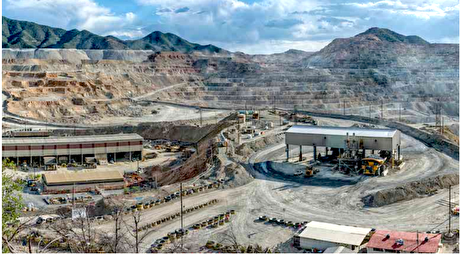

Plans to exploit Guinea’s bauxite mines have been stalled for decades amid lack of transportation infrastructure and the scourge of economic sanctions imposed on Iran by the West over the country’s nuclear program.

Procurement of bauxite has always been a challenge for Iran. The country’s only source of bauxite is Jajrom Mine located in the city of Jajrom in North Khorasan Province with reserves of less than 20 million tons.

Iran’s aluminum industry is operating way below the 470,000-ton-per-year aluminum ingot production capacity (at around 350,000 tons) due to shortage of bauxite.

According to Karbasian, mineral explorations undertaken in Iran during the past two years have sparked glimmers of hope for finding new reserves, though in the long run cooperation with global suppliers of raw materials is indispensable.

“Iranian mining companies can make up for technological and technical shortcomings of Guinea’s mining sector and in turn make use of the country’s mineral riches,” the Guinean minister said.

According to Magassouba, Guinea is home to 4 billion tons of proven bauxite reserves and that the mineral zone allocated to the Societé des Bauxites de Dabola-Tougue–the joint Iranian-Guinean company–holds over 70 million tons of the mineral.

Furthermore, the African country holds 10 billion tons of grade 65% iron ore, which can be exploited and processed using Iranian expertise, he says.

Iran holds a 51% stake in the bauxite project, which allows for production over 5,684 square kilometers once a fresh feasibility study has been conducted. Guinea holds the minority stake, according to a contract signed in 1992.

The partnership with the Guinean government was recently renewed for another 25 years and Iran is now awaiting a consultant’s recommendation by September on how to make the mine operational.

According to Bloomberg, Iran expects to issue a tender by the end of 2016 to build a pipeline in the African country to annually transport 4 million tons of bauxite to Conakry Port for shipment. The tender would be issued after an economic feasibility study is received by German consultants DMT GmBH.

During a tour of the Iranian Mineral Processing Research Center in Alborz Province, Magassouba said a group of Guinean mining technicians will soon be sent on a mission to IMPRC for mineral research training.

He also met with the top managers of Geological Survey of Iran and visited a number of industrial tile and ceramic producing companies during his two-day stay.

Iran is planning to produce 1.5 million tons of aluminum ingots per year, as stipulated in the 20-Year National Vision Plan (2005-25). To realize this ambitious target, Karbasian said, more than $10 billion of investment are needed.

Iranian aluminum producers are considering direct imports of alumina from major producers in the world such as Australia and India.

Head of ISAI Houshang Goudarzi says talks are currently underway with five alumina exporting countries to sign long-term import contracts which, if successful, will allow Iranian companies to purchase the raw material about $100 cheaper than their current sources.

Iran is a net buyer of alumina and has historically favored shipments from Australia. In recent years, Iran has often paid substantial premiums for Indian alumina.

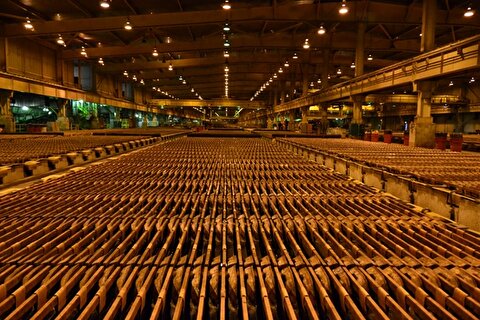

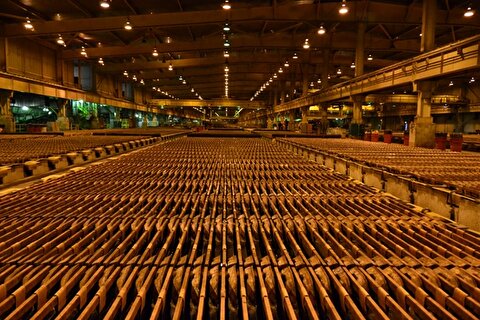

Bauxite and alumina represent the first two links in the value chain on the way to aluminum metal and, in turn, to aluminum products. Bauxite is the most common raw material used to produce alumina for aluminum metal production. The white powder alumina is produced by the refining of bauxite.

It is possible to replace bauxite with nepheline syenite beneficiation to produce alumina. Reserves of about 1.2 billion tons of this mineral have been discovered in Sarab City of East Azarbaijan Province and investments have been made to extract this mineral.

Nepheline syenite is about 20% cheaper than bauxite and its byproducts can be used for producing cement and sodium, potassium and phosphate carbonates. The government has put the Sarab Nepheline Syenite Mine out to tender and is seeking foreign investors to undertake the project.

USGS on Iran’s Bauxite

Iran is a minor producer of bauxite in the Middle East and North Africa region and globally. The country’s production of bauxite decreased 36% to 504,000 tons in 2015 and output continued to lag behind domestic demand from alumina and aluminum producers, according to the latest report by United States Geological Survey.

Iran Alumina Company, the only producer of bauxite and alumina in the country, operates the Jajarm Mine. The mine supplies about 36% of Iran’s annual domestic bauxite consumption, whereas imports account for the remaining 64%. The company also operates a 280,000-ton per year alumina plant in Jajarm, which meets about a quarter of annual domestic demand.

In order to increase bauxite production, Iran Alumina Company continued to explore deposits domestically in Kerman, Kohgilouyeh-Boyerahmad, Semnan and Yazd provinces as well as in Guinea.

In 2015, the company discovered deposits at the Ganou and Taash Mines in Semnan Province and was in the process of obtaining operating permits for mines in Kerman and Yazd provinces. It planned to build a 2-million-ton per year capacity alumina refinery (from bauxite) in Arak, Markazi Province, and a 200,000-ton per year alumina (from nepheline syenite) refinery in Sarab, East Azarbaijan.

In March 2016, Sinosteel Equipment and Engineering Co. Ltd. of China announced plans to build a 1.6-million-ton per year alumina refinery (formerly known as the Persian Gulf Alumina Project) to be supplied with imported bauxite from the Guinean project and an aluminum smelter with a production capacity of 350,000 tons per year.

Gold price eases after Trump downplays clash with Fed chair Powell

Copper price hits new record as tariff deadline looms

Brazil producers look to halt pig iron output as US tariff threat crimps demand

Chile’s 2025 vote puts mining sector’s future on the line

Gold price could hit $4,000 by year-end, says Fidelity

Three workers rescued after 60 hours trapped in Canada mine

US targets mine waste to boost local critical minerals supply

Glencore workers brace for layoffs on looming Mount Isa shutdown

Energy Fuels surges to 3-year high as it begins heavy rare earth production

Trump tariff surprise triggers implosion of massive copper trade

Maxus expands land holdings at Quarry antimony project in British Columbia

BHP, Vale accused of ‘cheating’ UK law firm out of $1.7 billion in fees

Southern Copper eyes $10.2B Mexico investment pending talks

American Tungsten gets site remediation plan approved for Ima mine in Idaho

Kinross divests entire 12% stake in Yukon-focused White Gold

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Trump tariff surprise triggers implosion of massive copper trade

Maxus expands land holdings at Quarry antimony project in British Columbia

BHP, Vale accused of ‘cheating’ UK law firm out of $1.7 billion in fees

Southern Copper eyes $10.2B Mexico investment pending talks

American Tungsten gets site remediation plan approved for Ima mine in Idaho

Kinross divests entire 12% stake in Yukon-focused White Gold

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming