China’s Major GE Manufacturer Resumes Production, Supply set to Increase

However, with the revival of graphite electrodes demand, the company decided to go revitalize itself and invited investments from across the country. Subsequently in April last year, a company called Fujian Jinshenglan Group successfully signed a contract to invest 100 million yuan in Heilongjiang Carbon’s revival.

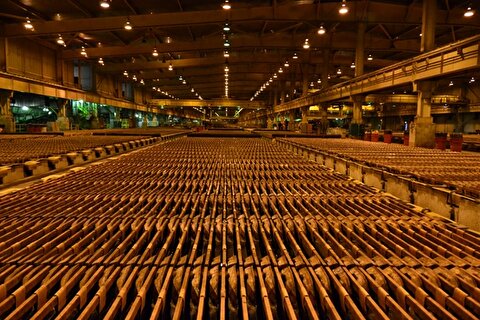

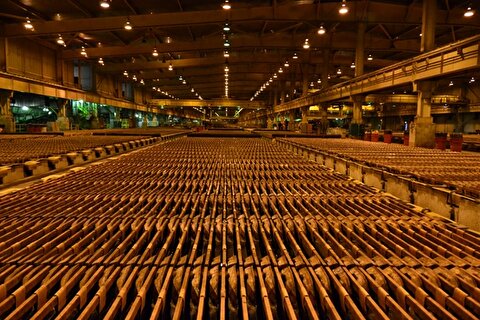

The company has built 33,000 tonnes of impregnation equipment, internal string graphitization furnace, 36-room ring roaster equipment which has injected new vitality into the old factory. This year the company will produce 30,000 tonnes of electrodes and the raw material, needle coke is going to be procured from local markets of Daqing (petroleum-needle coke), Fushun and Anshan (coal-tar pitch needle coke).

Heilongjiang Xinyuan Carbon Co. Ltd is the largest manufacturer of carbon products in Heilongjiang province for more than 40 years and possesses fixed assets of RMB 250 million spread across an area of 130,000 square meters. Before revamp, the company had a GE capacity of 25,000 tonnes. While this year the company will focus majorly on catering to the domestic market, in future it will target its GE exports to Russia as well as North-east Asia.

Lucrative export markets

The GE manufacturers in China are continuously increasing their production despite tepid domestic demand with the intentions to export their output. This has resulted in China’s GE domestic prices and export prices to move into reverse directions.

While in-house electrodes prices are touching new low in the country, export prices are relatively stable with minor fluctuations with the manufacturers focusing on the exports of good quality large size electrodes. As per the market sources, except for Southeast Asian and Turkish markets, the GE export prices in rest areas are still firm.

With the recent surge in iron ore prices, the gap between the profits earned via blast furnace steel and EAF steel have been reduced from 600 yuan per tonne to 50 yuan per tonne and thus it is expected that the EAF operating rates would increase steadily in the coming months, supporting the domestic electrodes demand.

Gold price eases after Trump downplays clash with Fed chair Powell

Copper price hits new record as tariff deadline looms

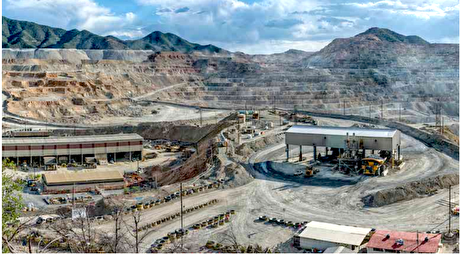

Chile’s 2025 vote puts mining sector’s future on the line

Brazil producers look to halt pig iron output as US tariff threat crimps demand

Gold price could hit $4,000 by year-end, says Fidelity

Three workers rescued after 60 hours trapped in Canada mine

US targets mine waste to boost local critical minerals supply

Glencore workers brace for layoffs on looming Mount Isa shutdown

Column: EU’s pledge for $250 billion of US energy imports is delusional

Trump tariff surprise triggers implosion of massive copper trade

Maxus expands land holdings at Quarry antimony project in British Columbia

BHP, Vale accused of ‘cheating’ UK law firm out of $1.7 billion in fees

Southern Copper eyes $10.2B Mexico investment pending talks

American Tungsten gets site remediation plan approved for Ima mine in Idaho

Kinross divests entire 12% stake in Yukon-focused White Gold

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Trump tariff surprise triggers implosion of massive copper trade

Maxus expands land holdings at Quarry antimony project in British Columbia

BHP, Vale accused of ‘cheating’ UK law firm out of $1.7 billion in fees

Southern Copper eyes $10.2B Mexico investment pending talks

American Tungsten gets site remediation plan approved for Ima mine in Idaho

Kinross divests entire 12% stake in Yukon-focused White Gold

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming