Future Concepts in Battery Foil Production: New Greenfield Aluminium Foil Production Plant in Hungary

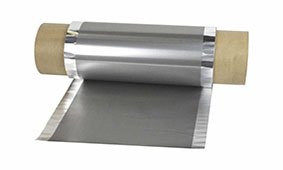

In the first expansion stage the scope of supply and performance comprise three OPTIMILL Foil Rolling Mills automated with OPTIROLL Control Systems and each run with a SUPERSTACK Rolling Oil Microfiltration System. A high efficient AIRPURE system will ensure the exhaust air purification of the rolling production for both, environment protection and rolling oil recovery. The processing of the primary material for the battery cell production will be made with OPTIFOIL technology, in concrete by using two SepaSlit Aluminium Foil Separators slitting the sensitive battery foil highly efficient. By comparison, the production per year is sufficient to produce 500,000 pure e-cars or correspondingly more hybrid cars.

This visionary major Greenfield investment is the first new aluminium foil production plant of this size in Europe for decades. In the run-up of the order placement it was Achenbach who consultatively supported the customer concerning the planning of the new plant’s layout and technology on the basis of the type and extent of the requested output, always keeping an eye on ensuring an optimal material and work flow concept at a maximal automation level. The trust Lotte Aluminium grants to Achenbach in advance as the supplier for nearly the complete machinery is enormous. André E. Barten, CEO, says: “Achenbach’s integrative solution is benchmark and blueprint of producing battery foils with highest quality assurance and highest productivity. It is an honour to be part of this new era of production in Europe.”

Initially, the positive experience with Achenbach machinery at the Korean production site in Gyeonggi-do was decisive for this order placement.

The new light gauge slitter for full-hard and soft-annealed aluminium foils, currently ready for dispatch to Lotte Aluminium in Gyeonggi-do, Korea

Beyond that, Lotte decided upon the new Achenbach OPTILINK® cloud-based IoT platform for an overall machinery networking to be installed at the new Hungarian production site. This platform allows the operator to control and operate his current production concerning both, quantity and quality at anytime and anywhere in the world. Technical highlights characterizing the new plant are essentially the Achenbach DVC Back-up Roll System with dynamically variable adaption of the crown, the Achenbach UniSpray® Coolant Distribution System with adaptive nozzle valve header, the hoseless roiling oil supply including hot spray system for roll cooling for optimum heat discharge, the highly efficient Achenbach UniDry® Rolling Oil Blow-off System for evenly dry strip surfaces, the automatic foil feeding system Achenbach FFS or the ironing roller system of Achenbach for highest rewinding speeds. Examples for technical highlights within the slitting machines are: a hydropneumatic, weight-balanced pressure system with innovative double diaphragm cylinder, a new cutting dust suction system in combination with an optimized scissors cut for thinnest aluminium foil, high ambition to keep the machine clean from dust and oil, machine utilization for the single-layer and double-layer foil production without additional set-up times.

To sum it up, the new made in Germany aluminium production plant in Hungary focussing on battery foils has all potential to become strategically, conceptually as well as technically down to details a ‘lighthouse project’ finding world-wide attention. For more information about the product, visit https://www.alcircle.com/achenbach

Background

The enormous demand for efficient lithium-ion batteries result on the one hand from the mega trend electric mobility: by now, electric cars resp. hybrid vehicles emancipated from being niche vehicles for idealists. The number of registrations increase rapidly worldwide in all developed countries and its advantages become clearer and clearer to the consumers. A respective charging station infrastructure and the people’s willingness to contribute to climate protection especially in city traffic are basic preconditions. On the other hand so-called ‘power-tools’ of daily life such as vacuum cleaners, leaf blowers, cleaning robots or battery hammer drills with efficient lithium-ion batteries and also industrial applications as in operating forklifts or drones are used more and more.

Gold price eases after Trump downplays clash with Fed chair Powell

Copper price hits new record as tariff deadline looms

Brazil producers look to halt pig iron output as US tariff threat crimps demand

Three workers rescued after 60 hours trapped in Canada mine

Gold price could hit $4,000 by year-end, says Fidelity

Chile’s 2025 vote puts mining sector’s future on the line

US targets mine waste to boost local critical minerals supply

Energy Fuels surges to 3-year high as it begins heavy rare earth production

Glencore workers brace for layoffs on looming Mount Isa shutdown

Trump tariff surprise triggers implosion of massive copper trade

Maxus expands land holdings at Quarry antimony project in British Columbia

BHP, Vale accused of ‘cheating’ UK law firm out of $1.7 billion in fees

Southern Copper eyes $10.2B Mexico investment pending talks

American Tungsten gets site remediation plan approved for Ima mine in Idaho

Kinross divests entire 12% stake in Yukon-focused White Gold

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming

Column: EU’s pledge for $250 billion of US energy imports is delusional

Trump tariff surprise triggers implosion of massive copper trade

Maxus expands land holdings at Quarry antimony project in British Columbia

BHP, Vale accused of ‘cheating’ UK law firm out of $1.7 billion in fees

Southern Copper eyes $10.2B Mexico investment pending talks

American Tungsten gets site remediation plan approved for Ima mine in Idaho

Kinross divests entire 12% stake in Yukon-focused White Gold

Gold price could hit $4,000 by year-end, says Fidelity

Southern Copper expects turmoil from US-China trade war to hit copper

Ramaco Resources secures five year permit for Brook rare earth mine in Wyoming