A single bar-delivery system for cooling beds, for bars ranging from 8 to 40 mm diameter

According to me-metals cited from mining.com, It combines the technology concepts of Twin Channel and roller table with aprons, allowing the delivery of bars with diameters from 8 to 40 mm into the cooling bed at speeds up to 60 m/sec.

At Marienhütte works in Graz, Austria, Danieli will revamp the largest part of the finishing area of the bar line, and among other changes will install a Twin Drum system eliminating the need for conventional aprons. A new cooling bed will receive bars up to 72 meters of length replacing the existing one for bars up to less than 40 meters.

Thanks to the new equipment and automation the line will become fully automated.

The equipment required for the process will be reduced, operations will be simplified, and operator safety enhanced. The upgrade will provide Marienhütte greater flexibility in production to meet evolving market demands while lowering overall costs.

The turnkey project includes disassembly, erection, and commissioning activities during a planned, three-week plant shutdown. The start-up is scheduled for the beginning of 2026.

source: danieli.com

Zimbabwe labs overwhelmed as gold rally spurs exploration, miner says

Cochilco maintains copper price forecast for 2025 and 2026

Samarco gets court approval to exit bankruptcy proceedings

Gold price stays flat following July inflation data

Mosaic to sell Brazil potash mine in $27M deal amid tariff and demand pressures

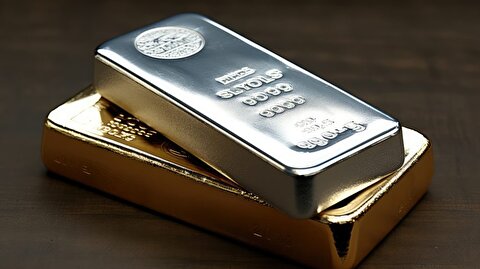

HSBC sees silver benefiting from gold strength, lifts forecast

Hindustan Zinc to invest $438 million to build reprocessing plant

Glencore seeks $13 billion in incentives for Argentina copper projects

Samarco gets court approval to exit bankruptcy proceedings

Roshel, Swebor partner to produce ballistic-grade steel in Canada

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

Afghanistan says China seeks its participation in Belt and Road Initiative

Gold price edges up as market awaits Fed minutes, Powell speech

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper

Glencore seeks $13 billion in incentives for Argentina copper projects

EverMetal launches US-based critical metals recycling platform

Iron ore price dips on China blast furnace cuts, US trade restrictions

Afghanistan says China seeks its participation in Belt and Road Initiative

Gold price edges up as market awaits Fed minutes, Powell speech

Flash Metals USA advances critical minerals recovery plant in Texas

Glencore trader who led ill-fated battery recycling push to exit

US hikes steel, aluminum tariffs on imported wind turbines, cranes, railcars

US appeals court temporarily blocks land transfer for Resolution Copper

Glencore seeks $13 billion in incentives for Argentina copper projects