Danieli olivotto ferrè multiline roller hearth furnace for alloyed-steel bar hardening and tempering

It processes alloyed steel bars in diameters from 15 to 100 mm, with an overall output up to 30,000 tons/year.

There, hardening (austenitizing and quench) and tempering, normalizing (in austenitizing furnace), soft annealing and stress relieving (in tempering furnace), are performed in continuous mode.

The key element used as common guideline to reach the performance targets is provided by the roll technology and design.

The equipment is designed with a new concept of multiline inclined and shaped rolls. Covered by Danieli patent, this specific solution is based on the concept of continuous rotation of selected bars during their handling inside the austenitizing furnace and the subsequent quenching system, in order to improve bar quality in terms of mechanical/metallurgical properties and excellent straightness.

Following, the excellent results already achieved:

- Hardness variation < +/- 1HRc along the surface of the bars

- Hardness variation < +/- 2 HRc from top-surface to core of the bars

- YTS = 850 ÷ 906 N/mm2

- UTS = 976 ÷ 1023 N/mm2

- Elongation = 15.6 ÷ 16.7 %

- Reduction Area = 60 ÷ 61 %

- Martensite percentage on the bar surface (by water quench) > 90%

- Martensite percentage on the bar core (by water quench) > 95%

- Decarburization < 0.003 * D (diameter of bar)

- Added bending on the bar < 1 mm/m

The plant is in industrial operation following a smooth commissioning period and final acceptance.

Energy Fuels soars on Vulcan Elements partnership

China extends rare earth controls to imported material

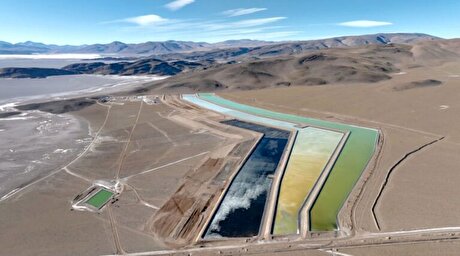

Galan Lithium proceeds with $13M financing for Argentina project

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Ukraine launches tender for major lithium deposit

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Critical Metals signs agreement to supply rare earth to US government-funded facility

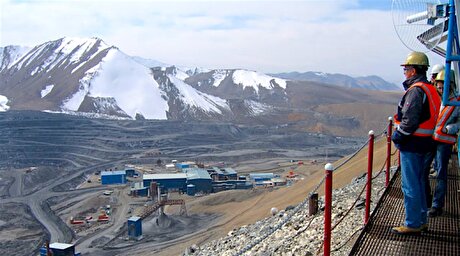

Kyrgyzstan kicks off underground gold mining at Kumtor

Equinox Gold kicks off ore processing at Valentine mine

India considers easing restrictions on gold in pension funds

Luca Mining expands Tahuehueto mine with Fresnillo land deal

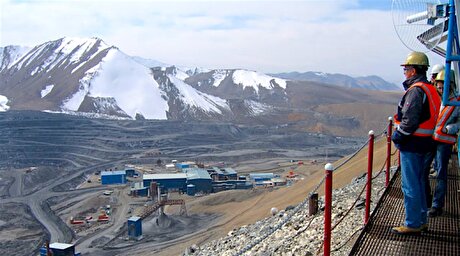

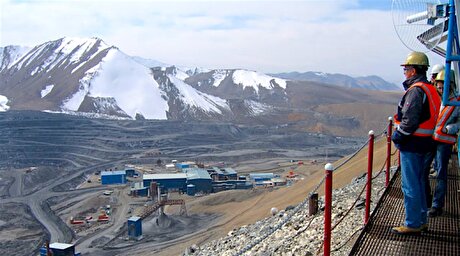

Kyrgyzstan kicks off underground gold mining at Kumtor

Ukraine launches tender for major lithium deposit

KoBold Metals granted lithium exploration rights in Congo

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

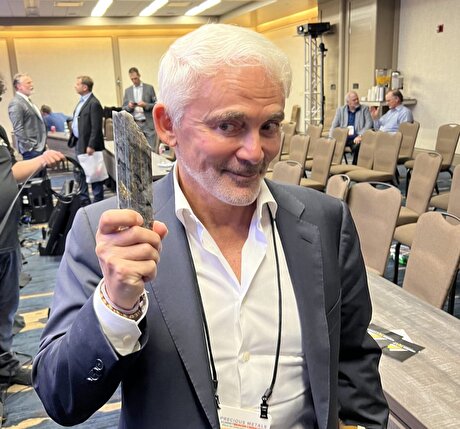

Giustra-backed mining firm teams up with informal miners in Colombia

India considers easing restrictions on gold in pension funds

Luca Mining expands Tahuehueto mine with Fresnillo land deal

Kyrgyzstan kicks off underground gold mining at Kumtor

Ukraine launches tender for major lithium deposit

Freeport Indonesia to wrap up Gresik plant repairs by early September

Energy Fuels soars on Vulcan Elements partnership

Northern Dynasty sticks to proposal in battle to lift Pebble mine veto

Giustra-backed mining firm teams up with informal miners in Colombia

Critical Metals signs agreement to supply rare earth to US government-funded facility